Steel Processing Services

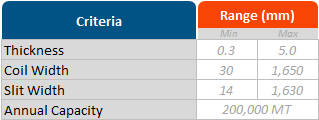

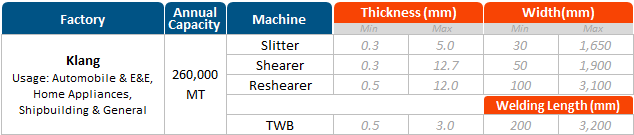

We offer slitting, shearing of steel mother coil into smaller slitted coils and sheets, as well as reshearing, welding or steel sheets. Our factories are equipped with state-of-the-art facilities to ensure customer's needs are met adequately. Reliability is our commitment to our customer. Additionally, in understanding the need of flexibility, customized sizes can be produced and packed in proactive packages.

We are ISO 9001, 14001 and 45001 certified. Customer can expects exceptional quality products and services resulting fewer return products and complaints, on time delivery, environment friendly manufacturing through efficient resource usage and reduction of waste, OHSAS compliance reducing risk of safety causing supply shortages.

Manufacturing Facilities

Klang Plant

Klang Plant

Process Overview

Process Details

Tailored Welded Blanks are semi-finished parts, which are typically made from sheets with different thicknesses, coatings or material properties. This process involves welding two or more steel sheets of different thickness and substance as well as partially changing their properties. After joining, these will be subjected to deep drawing or stamping.

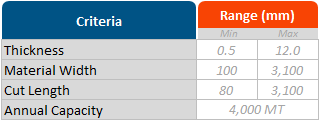

Tailored Welded Blanks are semi-finished parts, which are typically made from sheets with different thicknesses, coatings or material properties. This process involves welding two or more steel sheets of different thickness and substance as well as partially changing their properties. After joining, these will be subjected to deep drawing or stamping. This process involves cutting/shearing of sheet form material into smaller sizes according to customer requirement.

This process involves cutting/shearing of sheet form material into smaller sizes according to customer requirement.

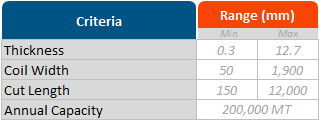

This process involves the use of shearing machine to cut/shear perpendicular to the direction of feeded steel coil by using rectangular knives according to specified sizes of length required by customer. We are equiped with advanced machines, and regular maintenance, resulting minimal amount of BURR and size tolerance.

This process involves the use of shearing machine to cut/shear perpendicular to the direction of feeded steel coil by using rectangular knives according to specified sizes of length required by customer. We are equiped with advanced machines, and regular maintenance, resulting minimal amount of BURR and size tolerance.

Slitting of steel coil is our core business operation. We have decades of experience in slitting high end steel coils for automotive, electrical & electronic industries, and low end general market.

Slitting of steel coil is our core business operation. We have decades of experience in slitting high end steel coils for automotive, electrical & electronic industries, and low end general market.